High-tensile steel wire net

With high strain performance, it is ideal for situations where there is a high risk of sudden impacts such as rockfalls, landslides, debris flows and mud flows. In addition, it also used to face rock slopes featuring large rock masses prone to failure as it can accommodate these high local stresses without sustaining damage. It can be installed with a low outlay of materials and man hours, which greatly reduces costs and construction time.

The technical performance of the system is dependent upon wire standard diameter, bundle configurations and the number of connection points to adjacent rings within the net panel.

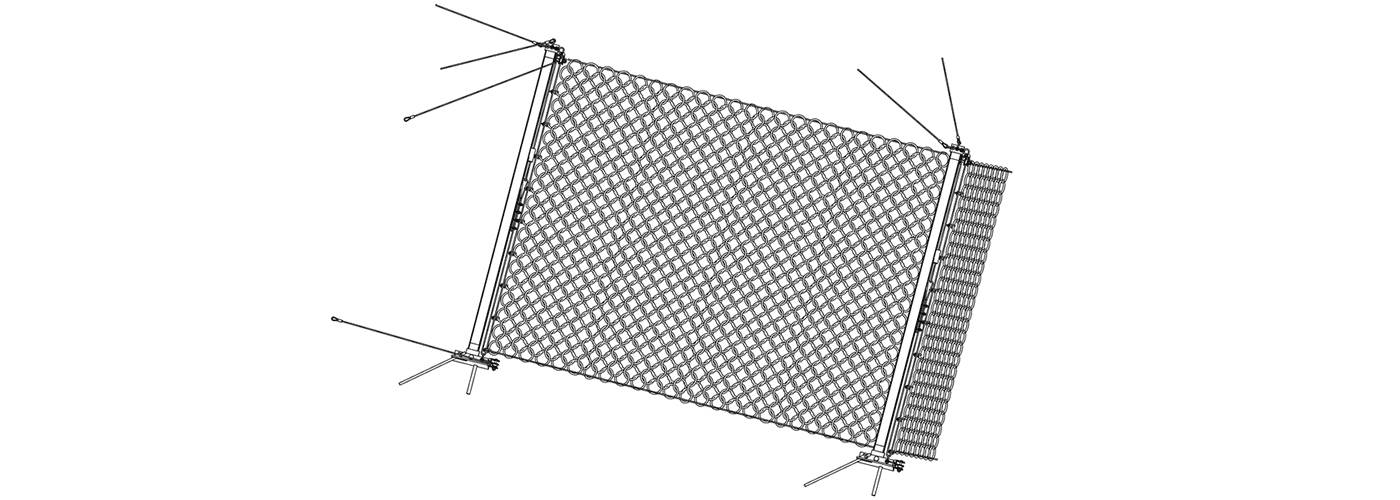

It generally consists of ring net, steel posts, brake rings, rope anchors and support ropes. Of which, ring net is the most important part of the whole system. The ring is manufactured by single wire with a tensile strength of 1770 N/mm2 and two ends of lap length not less than 100 mm. Twine together ring with steel or aluminum alloy fasteners in at least three hoop uniformly distributed locking, and one is located at the two ends of the joint, in addition to the edge ring hole, 4 rings each with its surrounding buckled together. Single tool can replace installation, repair and parts of the system. It is linked together by rings made of high tensile-strength steel wire which between 5 and 19 spirals are bundled together. It has good buffering performance through its deformation and outstanding energy absorption properties. As the ring net has a large mesh opening and cannot stop the movement of small rocks, it generally works with Rockcon® mesh or hexagonal mesh to increase the stability of rock slope.

| Type | RXE-500 | RXE-500-R4 | RXE-1000 | RXE-2000 | RXE-3000 | RXE-5000 | REX-8000 |

|---|---|---|---|---|---|---|---|

| Energy Absorption Capacity (kJ) | 500 | 500 | 1000 | 2000 | 3000 | 5000 | 8000 |

| Ring Net Size | R7/3/350 | R7/3/300 | R7/3/300 | R12/3/350 | R16/3/350 | R16/3/350 | R19/3/300 |

| Strands of Wire | 7 | 7 | 7 | 12 | 16 | 16 | 19 |

| Wire Diameter(mm) | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Ring Diameter(mm) | 350 | 300 | 300 | 350 | 350 | 350 | 300 |

| Supporting Rope Diameter (mm) | 12–18 | 12–18 | 16–22 | 16–22 | 16–22 | 20–22 | 22 |

| Number of U-Brakes for Approx. 80–100 RM | 4 × U-150-60/13 | 4 × U-150-60/13 | 4 × U-300-K1620 | 4 × U-300-R20 | 2 × U-300-R20 2 × U-400-R20 2 × U-400-R60/5 |

12 × U-300-R20 | 2 × U-400 6 × U-400-R20 6 × U-300-R20 |

| Distance between Posts (m) | 6–12 | 6–12 | 6–12 | 8–12 | 8–12 | 8–12 | 8–12 |

| Standard Barrier Height (m) | 2/3/4/5 | 2/3/4 | 3/4/5/6 | 4/5/6/7 | 4/5/6/7 | 5/6/7/8/9 | 6/7/8/9/10/10.5 |

| Max.Deflection Distance (m) | 3.60 | – | 4.36 | 5.80 | 6.97 | 8.15 | 8.45 |

| Residual Useful Height in the Impact Section | >50% (Cat.A) | >50% (Cat.A) | >50% (Cat.A) | >50% (Cat.A) | >50% (Cat.A) | >50% (Cat.A) | >50% (Cat.A) |

| Notes: Let's take the ring net size R7/3/350 as an example. Where R stands for ring net, 7 represents 7 circles, 3 stands for wire diameter, expressed in mm and 350 stands for ring diameter, expressed in mm. |

|||||||

High-tensile steel wire net

Low deformation

Pre-assembled

U-brake with stainless steel

Lightweight and unobtrusive

First-class corrosion protection

Ring Mesh

Steel Post

U Brakes

Brake Ring

Foundation Base

Rope Anchor

Support Ropes

Wire Rope Clips

Anchor Shackles

Ring Mesh

The ring mesh is made from high-tensile steel wire 3 mm thick and with a strength of at least 1770 N/mm2. It can be perfectly adapted to the terrain and is excellent for absorbing concentrated loads. To absorb impacts ranging from 500 to 8000 kJ, between 7 and 19 strands of wire are bundled into a ring measuring 30 or 35 cm in diameter. A fine secondary mesh also stops smaller rocks and stones.

Steel Post

H type post is installed onto the foundation base to support the steel wire ring net. It is corrosion and rust resistance to bear the harsh environments. Additionally, the steel post is high tensile strength to support the steel ring net. The arrangement of steel post is based on the terrain and usage environments.

U Brakes

Brake Ring

Foundation Base

Rope Anchor

It is made of high-tensile steel wires with 1770 N/mm2 tensile strength rope loop with double steel pipe and excellent corrosion resistance. It is insensitive to impact and is suitable for diverting forces in the direction of tension that can deviate by up to 30° from the drill axis without loss of supporting capacity.

Support Ropes

Wire Rope Clips

Wire rope clip, also known as u-clip or wire rope clamp, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-shaped bolt, a forged or cast saddle and two nuts. The two layers of wire rope are placed in the U-bolt. If the wire rope clips are not theft-proof type, the thread shall be secured with high viscosity glue.

Anchor Shackles

Anchor shackles have a rounded shape, which allows them to take loads from many directions without developing significant side load. It works great in applications that are temporary, or require repeated quick connections or disconnections. In this system, it generally used for force-locked connecting of two individual ring net mesh panels. If the shackles are not theft-proof type, the thread shall be secured with high viscosity glue.