High Tensile Strength

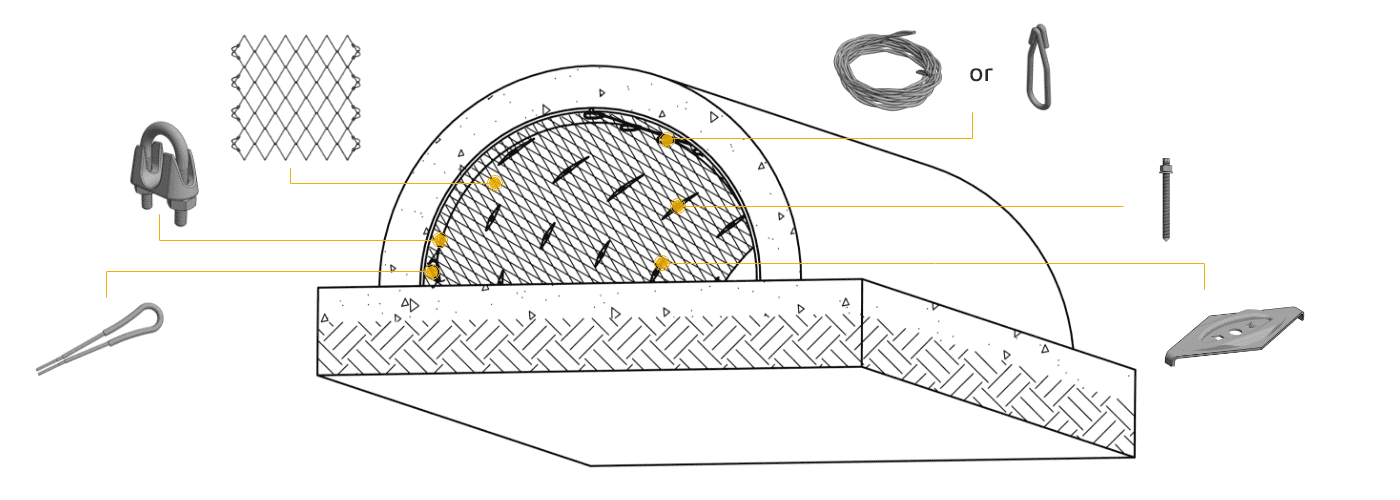

Mincon system is a kind of high tensile steel wire mesh system specially designed to provide surface support in either fall-of-ground or heavy rock burst conditions and ensure the work safety of underground workers.

It mainly consists of Mincon mesh, soil or rock nails, spike plates, connection clips and boundary ropes. Mincon mesh is made of high tensile steel wire, which allows it withstand significantly higher static and dynamic loads. It is generally fastened onto the roadway ceilings and surfaces tightly with soil or rock nails and spike plates through prestressed tension. This, in combination with its rhomboid mesh form, allows it adapting to almost all mine surfaces and helping to maximize contact with the roadway, thereby providing strong support for underground mining activities, preventing the movement of mining materials and ensuring the work safety of underground mining workers. As the Mincon mesh is often arranged by a mesh installation handler, it ensures minimum overlap loss, short installation period and less labor consumption. All these reasons make it a great alternative to welded mesh sheets or mild steel chain link mesh.

High Tensile Strength

Surface Fit

Reasonable Anchor Layout

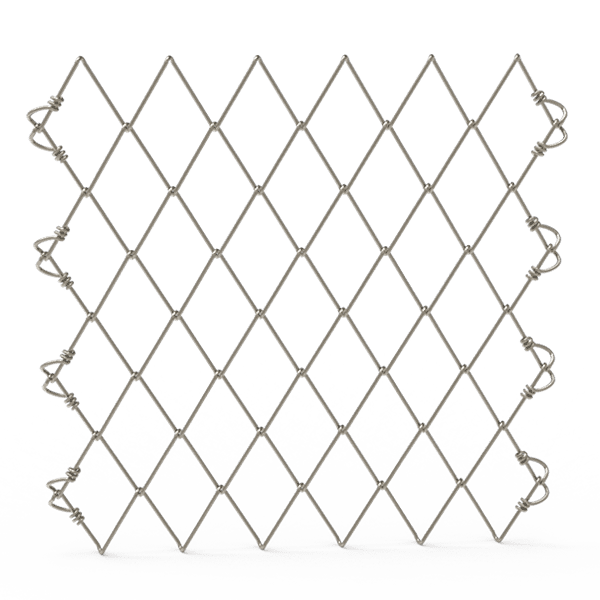

Mincon Mesh

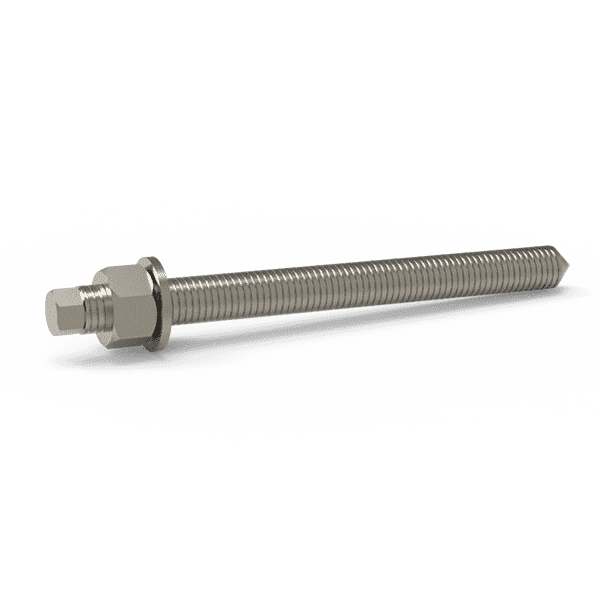

Soil or Rock Nail

Claw Type Spike Plate

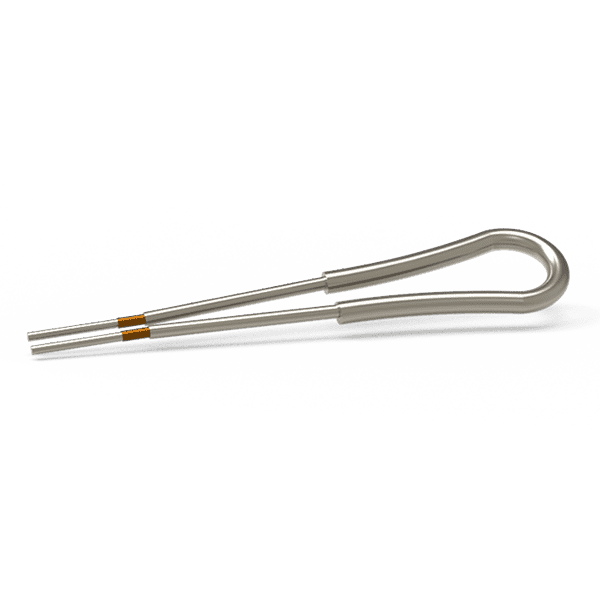

Rope Anchor

Connection Clip

Boundary Ropes

Wire Rope Clip

Mincon Mesh

It is the most important part of the Mincon system. It is a single twisted mesh made of high tensile steel wire with a diameter of 3 or 4 mm and a tensile strength of at least 1770 N/mm2, which makes the Mincon mesh have excellent resistance to mechanical stress and high impact forces. It features a rhomboidal-shaped mesh with a mesh width of 80 mm. Its rhomboid structure provides most stability for the geological conditions and can be tightly secured on the slope even on the irregular mountains. Meanwhile, its knotted ends can prevent loose and ensure the maximally stable of the structure. Besides, it makes the Mincon mesh rolls easy unrolled and installation.

Specification

High-tensile steel wire

High tensile steel wire has above 1770 N/mm2 tensile strength to withstand higher static and dynamic loads compared to traditional mild steel mesh.

Rhomboid mesh structure

The unique structure can transfer forces to the nails efficiently to prevent deformation. It can supply the best stability to withstand the fiercely impact.

Knotted ends

Knotted ends can prevent loose and ensure the maximally stable of the structure. Besides, it makes the Mincon mesh rolls easy unrolled and installation with minimum overlap loss.

Corrosion & rust protection

Tailor-made corrosion protection solution is provided according to your specific application environment requirements.

Lightweight

Outstanding strength-to-weight ratio makes transport and installation easier.

Smaller mesh for soil

High static and dynamic load capacities with optimal deformations to ensure the integrity of the Mincon system.

Soil or Rock Nail

It is commonly used with claw type spike plate to fix the Mincon mesh onto the mountain. High tensile strength and solid structure make it be long service life and in good conditions.

Specification

Claw Type Spike Plate

It is commonly used with nails to fasten the Mincon mesh onto the slope firmly. The unique claw design makes the spike plate be a more stable and firm structure.

Specification

Rope Anchor

It is made of high-tensile steel wires with 1770 N/mm2 tensile strength rope loop with double steel pipe and excellent corrosion resistance. It is insensitive to impact and is mainly used to fix the Mincon mesh onto the rock or soil slopes for easy and reliable boundary ropes tensioning/fixation. It can supply the whole stability to the slope and the Mincon system.

Specification

Connection Clip

It connects the neighbor Mincon mesh rolls firmly and supply whole protection for mountain and slopes. It is an alternative to the sewing rope and the connection is commonly without overlap.

Specification

Boundary Ropes

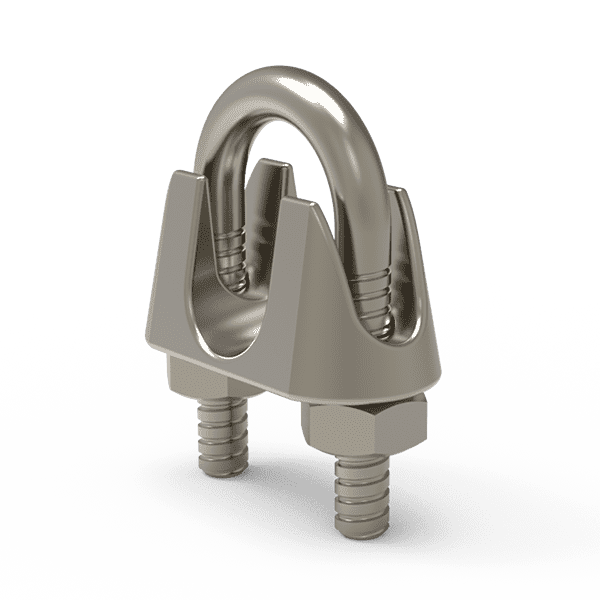

Wire Rope Clips

Wire rope clip, also known as u-clip or wire rope clamp, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-shaped bolt, a forged or cast saddle and two nuts. The two layers of wire rope are placed in the U-bolt. If the wire rope clips are not theft-proof type, the thread shall be secured with high viscosity glue.

Specification