High Tensile Strength

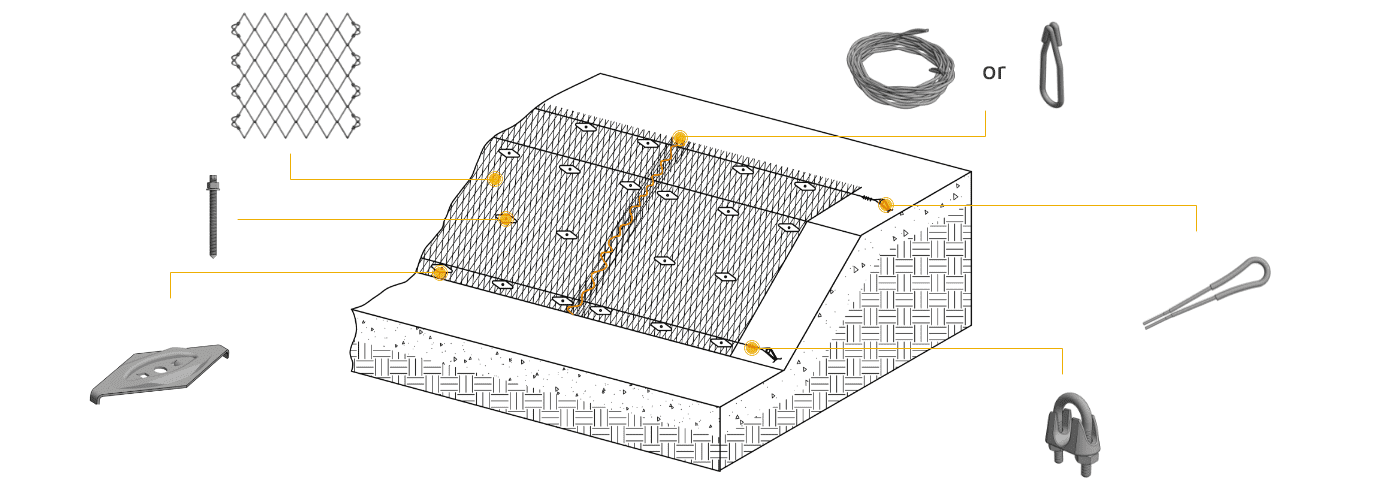

Rockcon® system is a kind of high tensile steel wire mesh system specially designed for rockfall protection, slope stabilization and landslide protection.

It mainly consists of Rockcon® mesh, soil or rock nails, claw type spike plates, rope anchors, connection clips and sewing and boundary ropes. Rockcon® mesh is generally fastened onto the mountain or slope surfaces tightly with soil or rock nails and spike plates through prestressed tension. This, in combination with its rhomboid mesh form, allows it adapting to almost all topographies and helping to maximize contact with the slope. Meanwhile, the firmly fastened Rockcon® mesh can effectively prevent the movement of small debris and absorb substantially high forces and transfer them onto the nailing. As a result, it guarantees the integrity of the whole mesh system and extends the service life of the mesh system. In addition, the Rockcon® mesh is an environmental-friendly wire mesh that allows plants growing on the mountains or slopes to contain soil erosion and increase the stability of mountains and slopes. All these features make it a cost-effective alternative to supporting structures, shotcrete walls and conventional protection measures.

High Tensile Strength

Topographic Fit

Reasonable Anchor Layout

Re-vegetation

Rockcon® Mesh

Soil or Rock Nail

Claw Type Spike Plate

Rope Anchor

Connection Clip

Sewing & Boundary Rope

Wire Rope Clip

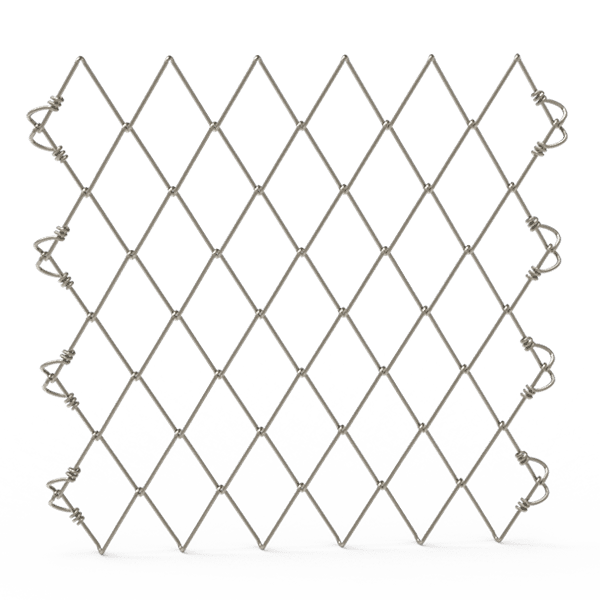

Rockcon® Mesh

It is the most important part of the Rockcon system. It is a single twisted mesh made of high tensile steel wire with a diameter of 2, 3 or 4 mm and a tensile strength of at least 1770 N/mm2, which makes the Rockcon mesh have excellent resistance to mechanical stress and high impact forces. It commonly has a mesh width of 45, 65 or 80 mm. Its rhomboid structure provides most stability for the geological conditions and can be tightly secured on the slope even on the irregular mountains. Meanwhile, its knotted ends can prevent loose and ensure the maximally stable of the structure. Besides, it makes the Rockcon® mesh rolls easy unrolled and installed.

Specification

Note: stainless steel wire mesh with a tensile strength of at least 1650 N/mm2 is also available.

High-tensile steel wire

High tensile steel wire has above 1770 N/mm2 tensile strength to keep the stability and tensioned structure for slope protection.

Rhomboid mesh structure

The unique structure can transfer forces to the nails efficiently to prevent deformation. It can supply the best stability to withstand the fiercely impact.

Knotted ends

Knotted ends can prevent loose and ensure the maximally stable of the structure. Besides, it makes the Rockcon® mesh rolls easy unrolled and installation.

Corrosion & rust protection

Special aluminum-zinc coating can extend the service life of Rockcon® system and protect system from sun exposure, corrosion and rusts.

Lightweight

Outstanding strength-to-weight ratio makes transport and installation easier. It supplies long-term stability for unstable slopes with minimal visual impact.

Smaller mesh for soil

Rockcon® R45/2 mesh has a smaller opening size and 2 mm diameter, which can stabilize the loose soils.

Soil or Rock Nail

It is commonly used with claw type spike plate to fix the Rockcon® mesh onto the mountain. High tensile strength and solid structure make it be long service life and in good conditions.

Specification

Claw Type Spike Plate

It is commonly used with nails to fasten the Rockcon® mesh onto the slope firmly. The unique claw design makes the spike plate be a more stable and firm structure.

Specification

Rope Anchor

It is made of high-tensile steel wires with 1770 N/mm2 tensile strength rope loop with double steel pipe and excellent corrosion resistance. It is insensitive to impact and is mainly used to fix the Rockcon mesh onto the rock or soil slopes for easy and reliable boundary ropes tensioning/fixation. It can supply the whole stability to the slope and the Rockcon® system.

Specification

Connection Clip

It connects the neighbor Rockcon mesh rolls firmly and supply whole protection for mountain and slopes. It is an alternative to the sewing rope and the connection is commonly without overlap.

Specification

Sewing & Boundary Rope

Sewing rope is an alternative to the connection clips to fasten two adjacent neighbor Rockcon® mesh panels. But there's overlaps when using the sewing ropes. Boundary ropes pass through the Rockcon mesh and then be fixed onto the anchor and enable the firmly stable.

Specification

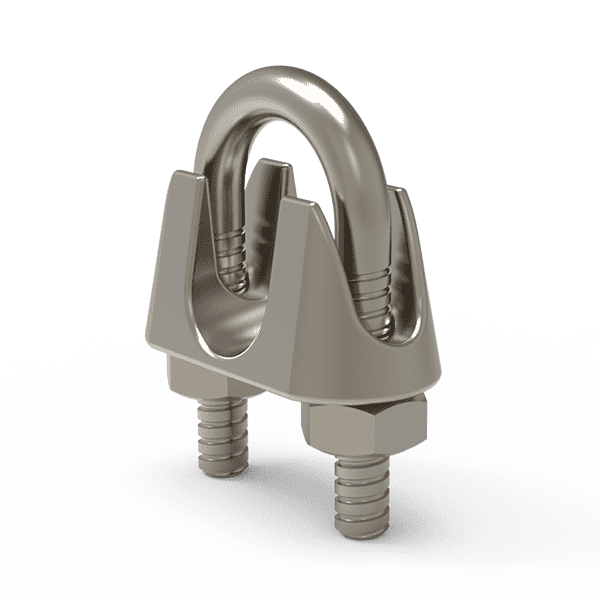

Wire Rope Clip

Wire rope clip, also known as u-clip or wire rope clamp, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-shaped bolt, a forged or cast saddle and two nuts. The two layers of wire rope are placed in the U-bolt. If the wire rope clips are not theft-proof type, the thread shall be secured with high viscosity glue.

Specification